1 Small Phillips Screwdriver (keyboard metal back small screws)

1 Medium Phillips Screwdriver (4 XL Keyboard to top case mounting screws)

1 Small cup or container (for XL case / Keyboard screws)

2 Sheets of White paper or better 2 white textured kitchen paper towels, not separated

1 Small set of diagonal cutters

1 Small Flashlight (LED)

Spray cleaner like 409

Paper towels for cleaning

1 Small Paintbrush (for cleaning the XL Key caps and black plastic XL Keyboard modules)

Optional Items:

1 Camera (for taking a picture of the XL Key cap locations)

Hot Melt glue gun

Compressed air

Bathroom Hair drier

A fine grade of Steel wool pad

Before you consider repairing / upgrading your old Atari XL Keyboard, you might consider 1st skipping down the end of this set of Best install instructions and check the Best Atari tech tips on cleaning of your 25+ year old XL Keyboard if it needs it.

Disassembly of the Atari XL Keyboard

Remove the XL bottom case screws and put them in your small screw container. Turn over the XL computer to it normal upright position. With the XL keyboard facing you, carefully lift the top XL case off the XL bottom case about 2 to 3 inches and stop. Look on the right side of the XL Keyboard around the function silver key caps. Under the XL function key caps / keyboard and between the top and bottom cases, you will see where the top XL Keyboard (it has 4 Phillips screws holding the XL Keyboard to the XL top case) mylar connecting strip is plugged into the 24 pin pinch connector on the XL motherboard in the bottom case. Now from the right side / end of the XL split open case half’s, reach in between the open cases half and with your left and right hands / fingers, grab each side (left and right) the XL Keyboard mylar connecting strip, as close to the pinch connector as possible and gently pull out / up evenly on the XL connecting mylar strip out of the 24 pin XL motherboard pinch connector. Next set the XL top case half with the XL Keyboard with the Key caps facing down. Next remove the 4 screws holding on the XL Keyboard onto the inside of the top XL case. Remove the XL Keyboard and set the XL top case aside.

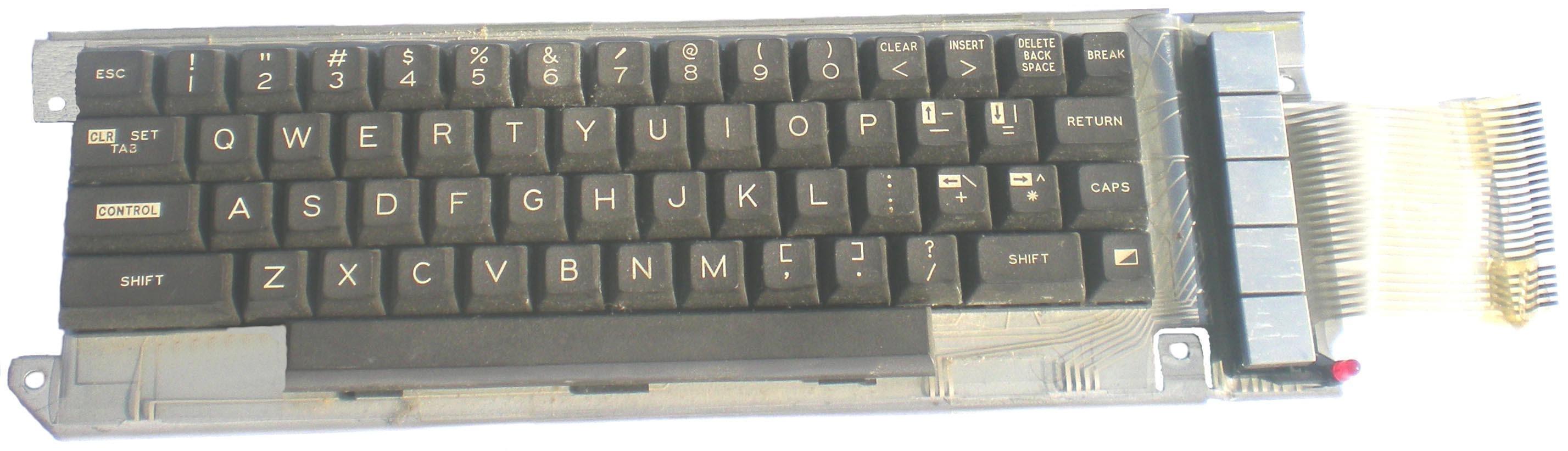

Lay the sheets of white paper or paper towel strip on your table / workbench. Put the XL keyboard on the paper so the key caps are facing up, the XL Mylar connecting strip is on the right side and the metal back is touching the paper. Something to notice at this time that will help you when you understand the reinstalling process of the New Best XL Keyboard Mylar. Note the main body of the XL keyboard assembly and the separate rectangular shaped right function module with its 5 Silver key caps.

Front close up side view of the stock Atari XL Keyboard Mylar Hump and dip down to the function module XL Keyboard mylar path

From a side view of the XL Keyboard at eye level, notice the open space between the XL main keyboard body and the XL function module. You will see part of the XL mylar that runs between these keyboard parts, has a slight hump up / bowed out section of the mylar, next you will see the XL Keyboard mylar then drops down to a lower level to the XL function module. This hump was done by the Keyboard designer to give the main XL keyboard main body mylar a bit of strain relief from the function module. Take a final look at the right side up XL Keyboard and note where the Red LED is located. On the inside of the XL Keyboard mylar there will be two small rectangular silver conductive pads that sit directly under this LED. You can use these small LED silver pads on the mylar as reference point on how to put the new XL keyboard Mylar on the XL Main black plastic body. Now turn over the XL Keyboard so the metal back is facing up, space bar at the 12 noon location and XL function module on the right side.

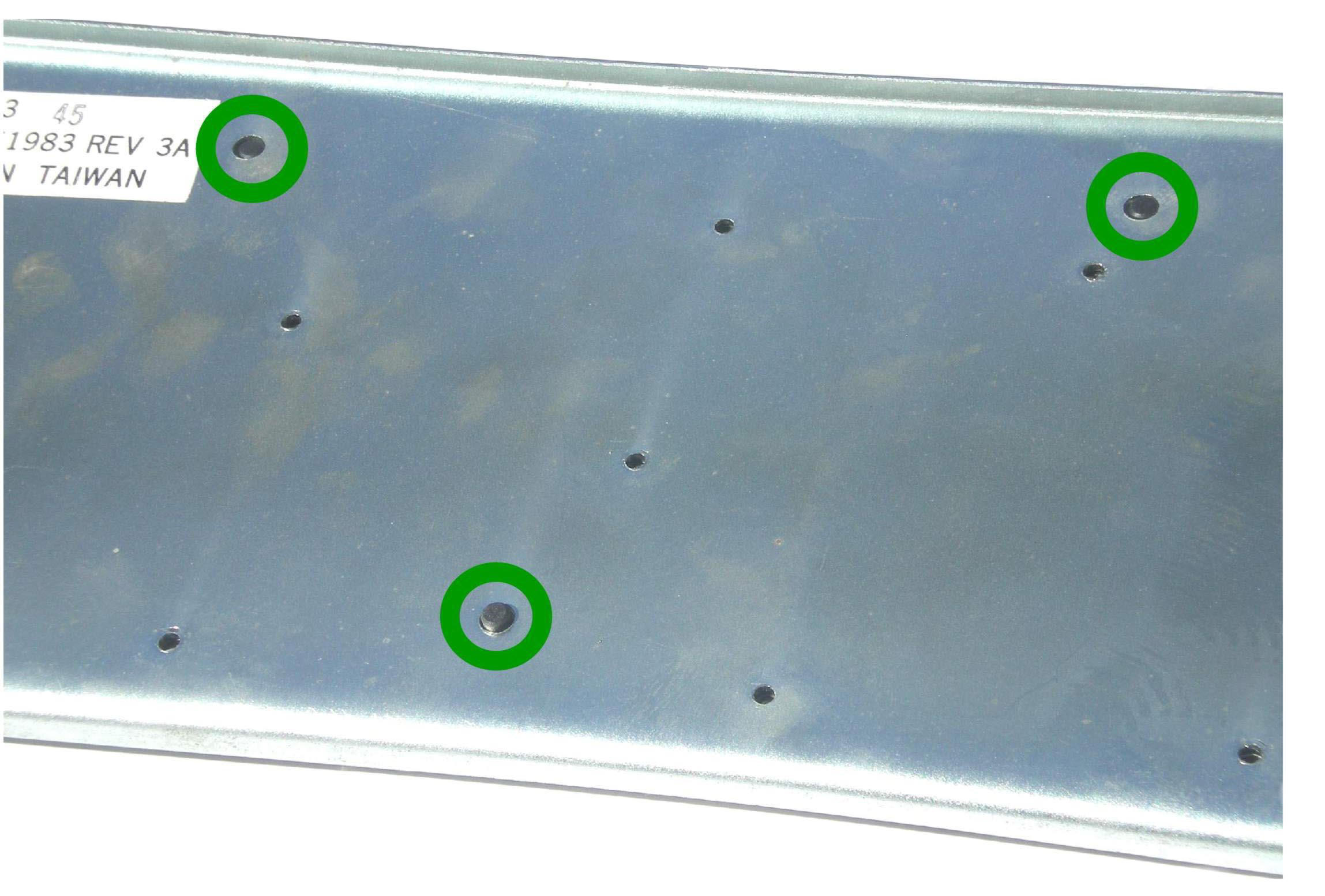

A close up view of the XL function key module area showing the 2 of 4 different XL Keyboard function modules (behind the metal plate) made. One version with 4 screws (2 of the small locating thru hole studs have screw threads in them, spaced 3 inches apart) holes, another version with 4 screw holes with 2 extra small raised thru hole locating studs spaced 1 1/2 inches apart no screw threads on those small locating studs (that come thru / sit above the metal plate) or 6 screw mounting patterns with two locating studs (spaced 1 1/2 apart) with screw holes. All of the XL Keyboards have the same Atari XL Keyboard part number and 3A Rev. level on them (white label or black silkscreen letters / numbers on the metal back plate), the only difference we can see, is one has 1984 date code (right one) and the other has a 1983 date code (left side). In theory Atari Engineering should of changed the XL Keyboard part number or Rev. level on the newer 1984 XL Keyboard version since the internal XL Keyboard Mylars were not interchangeable.

On the right side (see picture above) of the XL Keyboard loosen the 4 or 6 (depending the version XL Keyboard you have) small Phillips screws holding the right side XL function module on the metal backing. Remove all of the function module Phillips screws. Put the removed small Phillips screws in your small cup / container. Also note, depending the exact XL keyboard function module you have, some have two separate locating raised tits (see about 6 pictures down this page, the close up inside view of the separate function module, see the two green circles around raised tits) that come thru / fit into the metal back screw thru holes (the small Phillips screws also screw into these two locating tits). The XL function module may stick to the mylar / metal backing after you remove the small Phillips screws. You can remove the stuck on XL function module by gently rocking it side to side until it drops off the XL Mylar / metal backing. Now remove the function module from under the metal back / Mylar. Keep the now loose XL function module so the small exposed inside springs are facing up and the silver key caps are facing down. If you tip the function module to the right or left sides of the module, the 5 small function springs will come / fall out. Set the removed XL function module aside far enough away where it cannot get bumped over and again loosing the 5 small center springs. Remove the rest of the XL Keyboard small Phillips screws on the main Keyboard body / metal back plate, putting them into your small storage container.

General Information on the construction on the Atari XL Keyboard.

(You can skip this section, if you do not plan to remove any XL Key caps or the underneath white square key cap plungers with 2 springs.)

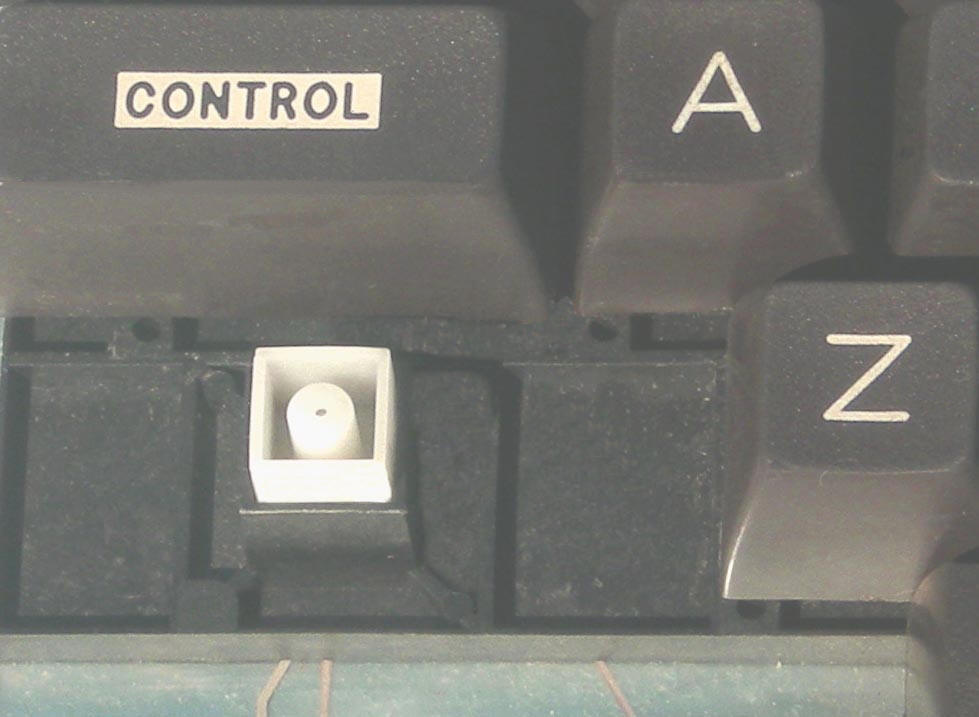

Close view of the Atari XL Keyboard left shift key cap (removed) square XL key cap white plunger.

For your Atari XL Keyboard information, there are two springs per each key cap white plunger (see picture below). One large diameter spring (push’s the white key cap plunger up when the key cap is pushed down) under each XL Key Cap and function cap square white plunger and a smaller spring (pushes thru the XL black keyboard plastic module to the inside and pushes the two separate sides of the inner XL mylar together (like a mechanical switch) in the center of the white XL plunger. If required the large and small XL springs can be accessed from the topside of the XL Keyboard (under the white square plunger). You can do this by using a small needle nose pliers and clamping on one of the 4 sides / walls of the white XL plunger and pulling straight up slowly. The white plunger center small spring can also be accessed from the inside of the XL Keyboard.

Close up view of an upside down XL Keyboard white square plunger showing the two different diameter springs. Notice two of the 4 bottom legs of the white XL keyboard key cap plunger, have 2 locking latches (7 PM and 2 PM locations, green arrows) on the top of each of those legs.

Atari XL Keyboard Atari inverse Video key cap and white plunger removed. When inserting the white square plunger with it two springs back into the XL main black body module, the white key cap plunger legs with the 2 locking latches on them, are to be installed in the 11AM and 4 PM or 2 PM and 7 PM corner locations into the above black square female cavity to snap and lock back into the XL black plastic body. On the right side function black module, the locking tabs on the white square plunger are to be inserted only into the 2 PM and 7 PM locations.

An Atari tech tip from our old 40+ year Atari Super tech: When reinserting the white XL plunger with into the XL Keyboard black body, turn the white XL Keycap plunger with the two springs upside down (see above white key cap plunger picture with the blue background) facing up and also turn upside the complete XL Keyboard. Then insert the white square key plunger (with its two springs) back / up into the upside down XL Keyboard main black plastic body (make sure the 2 locking legs of the XL white key plunger are at the 11 AM and 4 PM locations). This will prevent the XL white plunger springs from following out of place (and getting damaged or bent, if you try the same reinstalling key plunger procedure with the XL Keyboard upright position) when the XL key plunger / spring assembly is reinstalled.

Close up view of the backside XL Keyboard Metal backing plate less the small Phillips screws, showing the large aligning / locating black studs marked by the 3 green circles. The XL Space bar, behind the metal plate is located at the 12 Noon position on the backside of this XL metal plate.

Gently lift the XL keyboard Metal back off the XL keyboard black main body. In most cases the internal XL Keyboard old mylar will stick to the XL keyboard main black plastic body. A few cases during removing it, it will stick to the metal backing. This depends on the conditions (moisture levels, the amount condensation of years of heating up and cooling down from use, things spilled on top of the Atari XL keyboard) the XL keyboard has seen in the last 25+ years. As you are doing this and for a reference point, notice where the two small LED silkscreen rectangular contact pads (upper right corner, 1 PM location of the function module) are located on the old Atari XL Keyboard mylar and set the metal back in front of the XL black body like the picture below.

Inspection Point: Take the just removed XL Keyboard metal plate and inspect it to make sure the metal plate is dead flat / straight. Do an end to end (lengthwise) inspection of the top and bottom edges of the metal plate. If something fell on top of the XL keyboard in the past or somebody hit or punched the XL Keyboard top surface, this can bend or distort the metal backing plate. If the bent plate is used with the new Best Keyboard mylar, you could end up with rows of dead / non working XL keycaps. The XL Keyboard metal plate is a soft metal, that can be bent / reshaped flat again with a little effort.

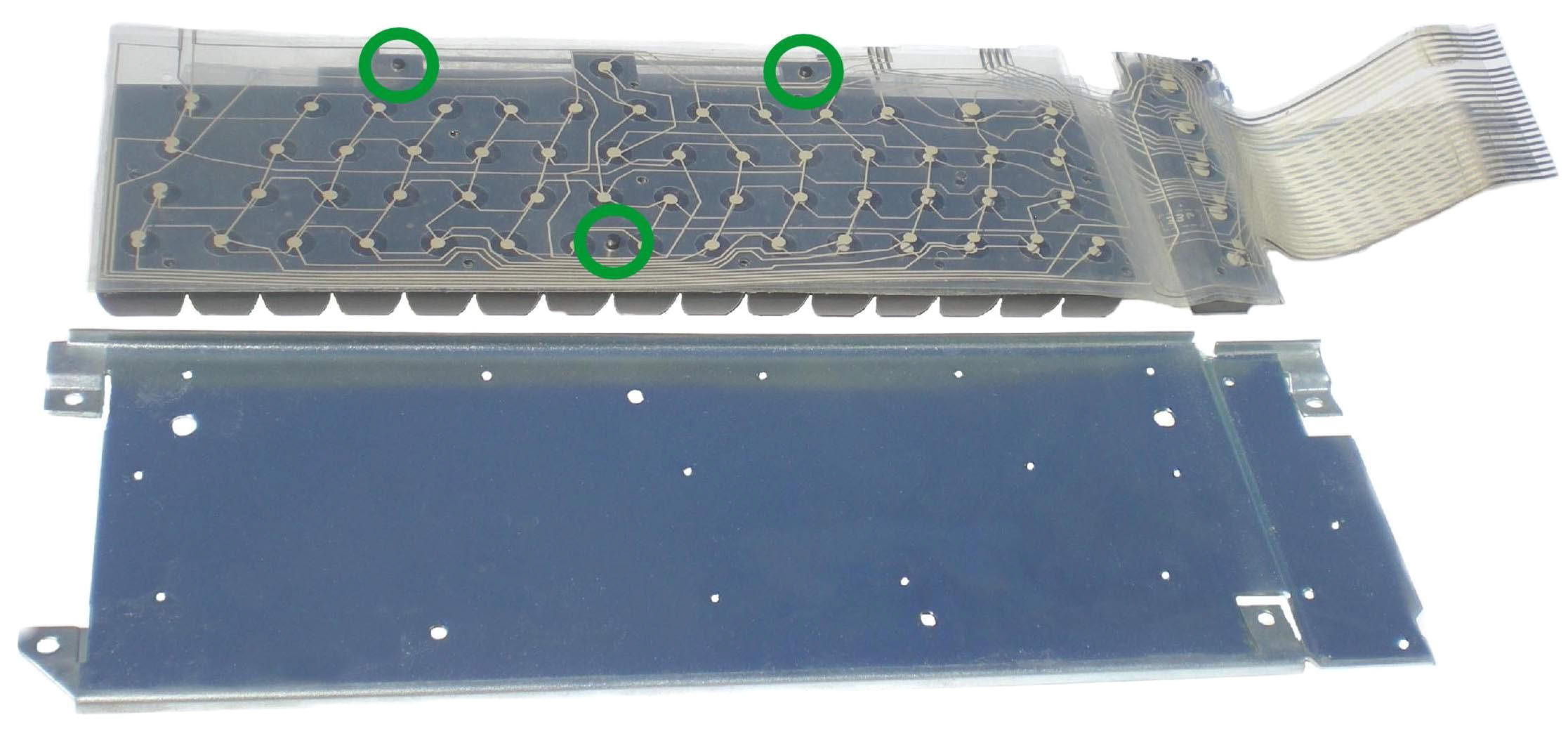

1st view of the inside of the dissembled Atari XL Keyboard. The XL Keyboard space bar (back side / key cap side of the XL black body) is at the top / 12 noon location and the LED on the XL function module is at the 1 PM location. Note the 3 green circles on the old XL mylar. Take a close of view of these 3 areas of the old Mylar. You will see 3 round large black locating / aligning studs (part of the black plastic XL Keyboard module, under the XL Mylar) that come thru the old XL mylar and metal back.

In any case, then peal it off the old XL mylar. You will notice that old 25+ year old Atari XL Keyboard internal mylar you just removed is a three layer design, one sheet of keyboard mylar folded over on itself with a third separate clear flat sheet of mylar with many holes punched into it, that is inserted between the folded over keyboard mylar. Note were the split opening side (along the bottom length) of the old XL mylar is located and clear sheet of plastic with the holes in it, was slide between the folded over XL Mylar layers. One side of the inside of the XL Keyboard mylar Traces and Connection pads are one side of a mechanical switch and the other inside side of the XL Keyboard mylar traces and mating pads are the other side of the mechanical switch. The thin clear flat sheet with holes in the center / between folded over mylar sides, keep the two half’s of the mylar switch pads from making contact / shorting with each other. So when a XL top key cap / white square plunger is pushed down on the outside / top side of the XL keyboard, the small center spring pushes on one side of the XL internal Mylar switch pad, pushing it thru the center mylar flat sheet open hole making it contract with the opposite side of the XL keyboard mylar mating side trace / pad, like a standard closing of a mechanical switch where two internal metal leafs making contact with each other

Reassembly of your XL Keyboard

Inspection of the XL Keyboard components before reassembly

1. 1st thing you will notice is there a lot of small foreign materials (dust, dried chemicals from years of dried up condensation and even rust from the small Philips screws used to hold the metal back onto the XL / function key modules and metal backing) on the inside top surfaces of the main XL black plastic body and separate right XL black function module. It is good idea to remove as much of this old foreign materials off the XL components as much as possible. One way to do this is to use a small paint brush and sweep off the foreign materials. But be very careful you do not snag / pull any of the small springs out of the main XL black module small spring holes and the function module small spring holes. If one of the small springs gets caught in the brush bristles or flung away in the brushing / cleaning process, chances you will never fund it again. So clean small sections of the XL black modules at a time looking for missing small springs or open spring holes in the process. You may have use a household cleaner like 409 dabbed on a paper towel (do not spay the cleaner directly on the black XL module bodies) it might cause the small springs to rust or cause any existing rust in the open small screw holes to spread after you closed up the XL keyboard) to remove the any stubborn stuck on foreign materials. Any large pieces of left foreign material left on the XL modules or metal backing plate will rub away at the New Best XL Keyboard mylar and maybe damage it with 10 to 20+ years of normal use. It would be a good idea to use a hair dryer on the areas of the black keyboard modules you just cleaned with a cleaning solution, to make sure it is completely dry.

2. Carefully lift the XL Keyboard main black body to eye level, keep the small springs in the main black XL Keyboard body small holes facing up. Without touching (pushing up the underside key cap plungers up) any of the XL Keyboard key caps, inspect the small spring levels to make sure they are all about the small level above or level with the main black XL module. See close up picture of a bad spring (red circle) below. Do the same side view inspection for bad springs on the XL function module.

Close up view of the XL main black keyboard black body. The 3 Green circles are of the XL mylar locating black plastic studs one large and 2 smaller locating tits (on the function module) with screw holes. The Red circle is a defective small spring, that sits above all of the other small spring levels. If XL keyboard is reassembled with the defective / longer small plunger spring, you will get the XL Keyboard stuck (key cap always pressed down / on) key syndrome.

3. If you find the tops of any small springs that are setting way above the normal level of the other springs in the XL Keyboard black body, in most cases that was done by the original Keyboard manufacture as a way to fix a marginal original new XL mylar switch problem (mylar switch half’s, not making proper switch contact). To make the problem XL Mylar switch work properly, the Keyboard manufacture stretched the small spring until the mylar switch half’s started to work / function. So if you do not correct this long over length small spring problem, when you install the New Best Upgraded / Enhanced XL Keyboard mylar and fully assembled it, you would find on the long small spring location(s), that XL keyboard key cap function mylar switch would be stuck closed / repeating the same character all of the time. So it is easier to fix this problem long spring when the XL Keyboard is apart but can be done when the XL keyboard is again full assembled again.

4. So if you do find some long small springs, with the tip of your finger, 1st push on the small spring head down very slowly (so it will pop back into its hole and fully seat) and release it slowly, to make sure it was not accidently wedged in the up position by accident in the small spring hole. If it still sites high, pull the long small spring out of its small hole and the drop it back into the small hole. Also double check to make sure nothing is pushing on that XL Keycap under the keyboard. If everything checks out and that spring is still high, that long spring length will have to be trimmed down to get the right exposed spring length. Pull the long length small spring out of it small hole. With the small pair of diagonal cuter, trim off one of the windings (it is best to do this trimming procedure in as small as possible length cuts as possible to approach the correct the right small spring length, rather then over shoot cut off too much spring length off). Take the cut end of the shortened small spring drop it back into XL black body small hole. When you have the correct exposed small spring length, make sure you drop the trimmed (sharp cut end of the spring) end of the small spring in to the XL black plastic body). So the trimmed / sharp end of the spring is touching the inside of the white XL square small plunger spring hole and the stock round / smooth end (non trimmed end) of the spring will contact the new Best XL Keyboard Mylar. If the trimmed end of the spring is installed up position, it will damage / cut into the new Best XL Keyboard mylar.

5. Now inspect the small springs for under length (an old defective / non functioning XL key cap function(s)). If you find any under length small springs, take the small spring out of the black XL keyboard small hole (by pressing on that key cap under the keyboard module). Stretch out this under length spring, in very small increments and drop it back into the XL black keyboard body small hole to test each time. It is better to slowly approach the correct small spring length, than over stretch the small spring length.

6. Do this same small spring length inspection / correction on the right side XL rectangular shaped function black body module, again keeping small strings facing up. If your XL function black body has the two locating raised tits with screw locating holes note where they are located. Not all of the different Rev’s of all of the XL keyboard function modules have the 2 small locating tits.

7. Now look at the top inside of the XL Keyboard main black body without the old mylar laying on it. At these approximate locations (11 AM, 2 PM and 6 PM) on the XL black body, locate three raised black larger round locating black studs (see early picture, 2 pictures above with old XL Mylar) of just opened up XL keyboard picture with the mylar with the green circles). The new Best Upgraded / Enhanced XL keyboard mylar will use these same three larger mating holes, to properly align itself to the XL keyboard black body.

Bests 40+ year Atari Super Tech experimented on 4 to 5+ completely different ways to reinstall the new Best XL Keyboard mylar on the main XL black keyboard body. One method proved to be the best and easiest method below.

Move the main black body of the XL keyboard out of your work area for now. We are going to work with the New Best XL keyboard mylar, black rectangular function module and metal back for now.

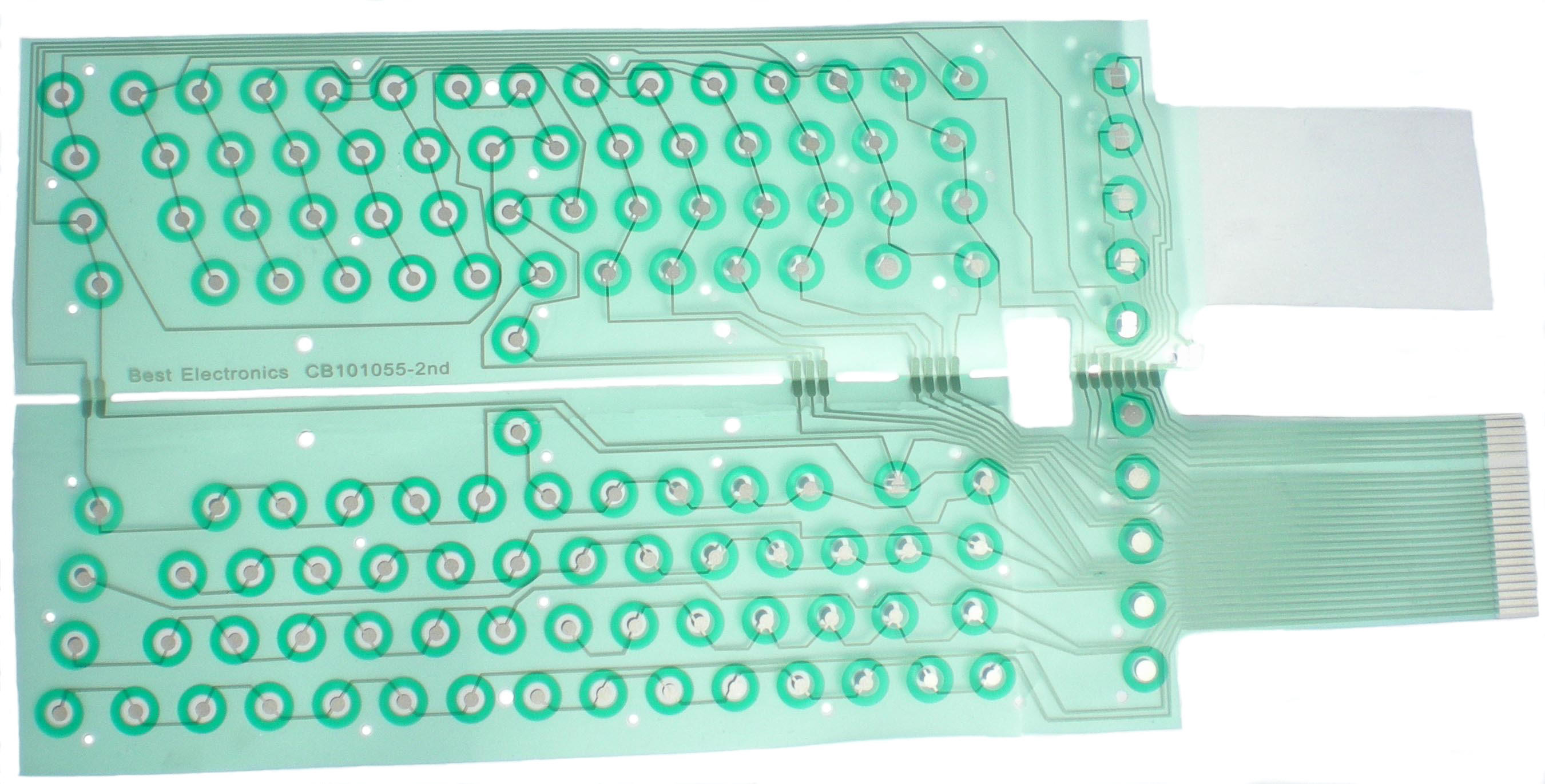

The New Best XL Mylar was shipped to you in its final folded over position for final assembly with the silver contact points on the inside of the folded over mylar surfaces. Bests Atari Super Tech recommends you do this part of the XL Mylar reinstall, in the 9 AM to 3 PM alignment / reassembly procedure. Lay the New Best XL Mylar by itself, so the connecting strip is on the right side (3 PM location and the left end of the XL mylar end at the 9 AM location). The lengthwise split / opening of the Best New XL Mylar half should be along the bottom edge of the Mylar as it sits on the white paper towel. Locate the 2 larger silver LED pads on the Best XL Mylar, they will be on the top right hand corner of the mylar. On the left top side, you will see the Best Electronics name and part number is upside down.

On the XL function module locate the mating 2 metal LED metal contact pads on the black rectangle shaped function module (also check these 2 LED internal metal leaf contacts for any rust, corrosion, foreign materials or a metal leaf bent at the wrong contact angle and correct any of these problems). Now slide the XL black rectangular function module (LED metal contacts in the upper right corner) under far right side function module portion of the Best XL Keyboard mylar. Align the function module (that is sitting under the XL keyboard mylar), so all of the 4 to 6 small Phillips screw thru holes in the new XL Mylar align up. If your rectangular XL function module has the two small aligning tits (see picture above, two green circles), as you are sliding this module left under the new XL mylar, you will feel the XL module slide / snap up / lock into its right location on the Best Mylar. Verify this and make sure the 4 to 6 screw holes in the new Best XL keyboard mylar are over the 4 to 6 empty screw holes in the XL function module that is sitting under the mylar function area. With your right hand / finger, hold down the new XL keyboard aligned mylar onto the black function module top surface. With your other hand, grab the XL Metal plate and align the function module right side of the metal plate with its thru (4 to 6) screw holes with the same mating ones in the held together mylar / function module stack you are holding with your right hand. Once properly aligned, remove your finger holding down the mylar on the top of function module and gently let the XL Keyboard metal plate down onto the XL Keyboard Mylar and the black function module below it. You might have slightly move around the underneath XL function module / mylar stack up, until you feel the two small locating tits (if your XL black function module has the locating tits) on the XL function module lock / snap up into the XL Keyboard metal plate function area.

Before you reinstall the 4 to 6 small Phillips screws on the XL top side of the

Metal plate function area, do a quick double check with the flashlight in each

of the function metal plate screws holes, to make sure the underneath mylar has

not shifted (and the thru holes in the mylar are no longer in the right

locations / exposed). Readjust the XL mylar location if required. Then

reinstall the 4 to 6 small Philips screws into the XL function area metal

plate. If the small Phillips screws simply do not drop thru the metal back

during reinstallation, check that hole(s) to see if the mylar sheet has shifted

under the metal plate again.

An Atari XL Keyboard Mylar Tech tip from our 40+ Atari Super tech. Take the Anti Tarnish Silver Saver paper shipped with each Best Upgraded New XL Keyboard mylar and (note which side of the Silver Saver paper is the Silver Anti Tarnish treated side, it is opposite the printed side) cut it up to thin strips. Lay (between the folded over layers of the new Best XL Keyboard) those strips of Silver Saver treated paper so the treated side faces close to the exposed silver conductive round pads, in non critical areas (Not over round conductive silver pads and not over / near the dark Green non conductive round rings around each conductive silver round pads, Not over thru screw holes, Not over the aligning studs). Remember that both insides of the New Best XL mylar surfaces have conductive silver dots, so you will have to stack 2 strips / layers of the Silver Paper thin strips (printed side touching the second thin strip printed side) back to back to be effective preventing any Silver oxidation inside the XL Keyboard body years down line. But adding the Silver Saver thin paper strips between the folded over XL Keyboard mylar halves, may make the installation of the New Best XL Keyboard mylar a lot harder for less skilled Techs / Installers.

Now that XL Keyboard function module / new Best XL Mylar sub assembly is done, take the main body of the black plastic XL keyboard module (XL Space bar across the top / 12 noon location) and slide it under new Best XL mylar / metal stack, starting from the left side to right side. Stop sliding the XL black main body to the right leaving about 3/8 of an inch of the black XL module left side / length is still exposed under the left side / length of the metal back (see picture below). Next we have to do a top to bottom alignment of the XL black body to the metal backing plate.

Upper left corner of the back of the XL Keyboard. Purple arrows are pointing to the same mating screw hole.

Locate the upper left corner of the exposed XL keyboard black plastic body (see above picture). In the upper left corner of the XL metal backing plate, locate the left upper extended metal mounting tab / ear with the top XL top case mounting screw hole in it and its bottom ˝ inch wide metal edge below the keyboard mounting screw hole. Align the upper left corner / top edge (like the above picture) of the exposed XL black body so it sits about 3/16 inch below the bottom edge of the upper left metal screw tab / ear. Not shown in the above picture, the Best XL green Mylar will be sticking out about 1/8 inch past the left edge of they XL Metal plate.

Holding the new Best Mylar and metal plate together, next lift the far left side / edge up the XL metal plate to about a 45 degree. In this lifting procedure, there is high chance some of the small springs might get pulled / sucked out of there small mating holes, so again check the XL main black body top surface for any missing small springs / empty small spring holes. Still hold the XL metal back at the 45 degree angle, now let the new Best XL Keyboard mylar gently lay flat on the XL black plastic keyboard body. With your free hand, align / move the Best XL Keyboard mylar / metal plate subassembly to the left slightly. Keep moving this subassembly to the left until the 3 larger thru aligning holes in the Best XL Keyboard mylar are in line with the 3 mating larger raised black studs (11AM, 2PM and 6 PM) on the XL bottom black plastic body. Lock (press down the Best XL Mylar down in those 3 locations) so the Best XL Mylar locks down onto those 3 raised large diameter locating studs. Once this is done, just gently lay the XL Keyboard metal plate down on the Best XL Keyboard mylar / XL main black plastic body stack up. Note none of the XL 14 screw holes or 3 locating studs in the metal XL board metal plate will not align up with the XL main black plastic module mylar stack up below the metal mounting plate for now. Put your left hand or finger on the far left side / edge of the main black plastic keyboard module (to prevent it from sliding to the left). Next gently side the XL metal backing plate (with the already installed right function module / Best Mylar) to the left very slowly until the left metal edge of the metal back is even with the left edge of the underneath main black plastic keyboard module (the Best XL green mylar will stick out about 1/16 inch to the left of the Metal plate). At this point, you should feel the metal plate drop onto the 3 main locating studs in the underneath main black keyboard module / mylar stack up. If the metal back does not drop onto the 3 large plastic locating / aligning black studs on the main black keyboard module, a few very very minor direction changes up / down / sideways changes in direction of the metal backing plate, should get it to drop onto the 3 large locating studs. Again with your flashlight, do a quick check of the tiny 14 screw holes in the metal plate, to make sure all the mating thru / open screw holes in the underneath New Best XL keyboard mylar are properly aligned with the screw holes in the XL back metal plate.

When you start to reinstall the XL Keyboard small Phillips screws back into the XL Keyboard metal plate, do like an auto mechanic does when reinstalling the lug nuts to hold the tire rim / wheel on to the mating car axle, stagger them. The 1st one in the upper left at 11 am position and the next one at 4 PM and then 2 PM and 8 PM positions and so on. This will make sure you will put even pressure on the XL Keyboard metal back as you are tightening down the small Phillip screws and on the new Best XL Keyboard mylar inside.

Now flip over the newly assembled XL keyboard. Do a front side, eye level side view of the XL keyboard. You will see this XL Keyboard assembly procedure put the proper mylar hump between the Main XL keyboard module and the left side XL Keyboard function module.

Before you install you Best XL Upgraded keyboard into the 600XL / 800XL Top plastic case, you should run a dry test run on the newly upgraded XL Keyboard. Put the sheets of white paper or paper towel length left to right, over the XL motherboard chips that sit under the XL keyboard. This will prevent the metal backing on the XL keyboard from shorting out on the XL motherboard chip top legs. Now set the XL Keyboard on the XL motherboard. From the right end of the XL bottom case, lift (angle up slightly) the right side (function module side) of the keyboard assembly. With your left and right hands / fingers, grab onto / pinch the Best XL Keyboard mylar connecting strip ends on the left and right sides of the XL keyboard mylar connecting strip very close the end of the mylar connecting strip end. Note some Atari 600XL motherboards use an XL Keyboard connecting mylar small very thin PCB daughter / interface board (with some resistors mounted on it and another 24 pin female pinch connector on it). This 600XL daughter board was used because there was not enough space on the tiny 600XL motherboard to install those keyboard resistors, compared to the 800XL motherboard that has those same resistors installed on the 800XL motherboard right next to the 24 pin connector. So you may have to remove this 600XL small keyboard interface / daughter / adapter board 1st and install the new Best Mylar connecting strip into it and then insert this keyboard subassembly back into the main 600XL Keyboard mylar pinch connector. Slowly insert the XL Keyboard connecting strip into the XL black 24 pin motherboard pinch connector until you feel it bottom out. You will now notice how much easier it is install and safely remove the Best XL Keyboard mylar connecting strip into the pinch connector with the new extra clear enforcing strip end attached to the back side of the Best XL mylar connecting strip.

Turn on your Atari XL Computer and test all of the key cap functions in XL Basic, to make sure they are working right. Next turn off your Atari XL computer. Insert an Atari game cartridge and then turn on the XL Computer. Test the XL right side 5 Function keys to make sure they all work correctly.

If all checks out good, turn off the XL computer. Again with two pinched together fingers on either end / side of the new Best XL keyboard mylar, gently pull the Keyboard mylar connecting strip out of the XL motherboard 24 pin female connector.

A couple of final Best Atari tech tips on reinstalling your XL upgraded Keyboard into the XL top plastic case.

1. Install the XL keyboard back into the XL top case, but do not fully tighten down the 4 large Phillips mounting screws. Check all of the outside XL key cap functions that sit very close to the inside of top, bottom, right and left sides in the XL top case keyboard opening. Make sure none of the XL Key caps do not drag / bind on the XL top case inside keyboard opening. You may have to reposition the XL Keyboard, slightly up / down / right or left so all of the outside XL Key caps / function silver key caps work fine. When everything looks / works on the XL keyboard keys, then tighten down the 4 main Phillips keyboard mounting screws.

2. When you are closing up the XL Top and Bottom case half’s, because of the new longer / extended Best XL keyboard connector strip, it might bow outward toward / between the closing XL case top and bottom halves, so if are not careful you will damage / pinch the new Best XL keyboard mylar between the XL case half’s as you are closing it up. One of the final things you want to do, as you are closing up the XL case halves, with one of your small fingers, push in the bowed out XL keyboard mylar connecting strip (between the case halves), so it bows inward and under the XL keyboard back metal plate. Now close up the XL cases and install the XL case screws.

Is your 25+ old Atari XL Keyboard dirty, dusty and showing it age?

One thing to consider before doing the installation of the Upgraded / Enhanced Best XL Keyboard mylar, is this a good time to clean your stock old XL top side of the keyboard? New Internal Best Upgraded Keyboard mylar, a cleaned New looking Atari XL Keyboard. Here are a couple of different ways to clean your old XL keyboard.

1. Turn the old stock Atari XL keyboard upside down (so the key caps are facing down). With the small paint brush bristles facing up toward the upside key caps, brush all around the XL key caps, spaces, rows and gaps removing as much foreign material as possible.

2. If you have access to compressed air, again with the XL Keyboard upside down, blow out as much foreign material as possible.

3. If your XL Key caps still look dirty, again with XL keyboard upside down, spray a very light mist / coat (not enough to create drops of spray cleaner falling off the key caps) of the spray cleaner like 409 on the upside down XL Key caps. Let the XL key caps soak for a minute or so. Then with the small paint brush, again brush all of the upside XL key caps cleaning off as much dirt and grim as possible. If your XL Keyboard is very dirty, you may have to rinse off the end of the small paint brush with water several times, during the upside down cleaning process. You can let the cleaned XL key caps air dry (still with the keyboard upside down) or carefully use the compressed air to blow off, in a downward angle and not directly at the tops of XL Key caps (you will blow the cleaning solution into the inside of the XL keyboard new or old mylar) to remove the excess spray cleaning solution. A third way to dry the cleaned XL Keyboard is with a hair dryer set on Medium heat. Again blow the hot air at a downward angle (at the inside of the key caps) and not directly up at the tops of the XL Keycaps (forcing the cleaning solution into the back black XL keyboard modules / Mylar)

4. The final cleaning method is completely remove (Before you remove all of the XL Keycaps it would be a good idea to take several pictures of how all of the XL keyboard key caps are arranged. It would also be a good idea to take close up pictures of how the XL space bar and the underneath attached dancing metal bar and the angle of the left and right plastic brackets and how they are attached to the underside of the space bar) all of the XL key caps (without pulling off the white square key cap plunger) and soak them (for 10 to 15 minutes) in a dish pan full of warm water and some dish cleaning soap.

Best Atari XL Tech Tip: After being installed on the white square key cap plungers for over 25+ years, you will find that some of the XL Key caps have bonded themselves to the inside of the white square plungers. So when you try to remove / pull off the XL Key cap, you will find you will also pull off the white square stuck on plunger out of the XL black body module. If this does happen stop, do not fully pull out the white plunger out of the XL black body module. If you can not see the 2 springs under the white square plunger (if you do see the 2 springs remove the key cap / plunger fully. Then use the keyboard upside down tech tip described earlier in this article, to reinsert the XL key cap / plunger back into the black XL module) slowly push XL Key Cap and stuck on white square plunger subassembly back into the XL black body module until you feel the white plunger 2 locking legs, lock the white plunger back into the XL black body module. To prevent this from happening again, on the same key cap subassembly, gently rock the XL Keycap slightly right, left, up, down directions on the white plunger. You will find this will break the 25 year bond between the XL Key cap and underneath white plunger.

You may have to use a plastic dish brush to fully remove the 25+ years of stuck on dust, dirt and stuck on grime on each XL key cap. Clean each XL Key cap one by one.

5. If you do clean your XL Keyboard with the new Best XL keyboard already installed, after it is completely dry, it would be idea to retest the old XL Keyboard in the XL bottom case again before you do the final reinstall into the XL top and bottom cases.

Possible problems and their Atari fixes on the Best XL Keyboard Mylar Installation

1. All of the XL keycap function fine. But one requires a little extra pressure to make that keycap function to work properly or does not work at all. This symptom can be caused by many different reasons. A Phillips screw (on the metal back plate) that is not fully tighten down under the XL Keycap with a problem. A short center spring length, a warped (concave) section of the XL Keyboard black plastic body module, slightly warped (outward) metal backing around that keycap / mylar section that is not near a XL Metal backing screw hole location. Over stretching the small center spring (under the white key cap plunger) will fix this problem. You can go back into the inside keyboard (remove the 14 small screws) and stretch that small spring location. You can also pull off that XL Keycap and white square key cap to get access to the two springs.

2. A few of the XL Key cap functions do not work at all. 1st check all non functioning XL key cap functions for missing small center springs under the white square key cap plunger. If the small springs are present, will have to stretch the center small spring length until the XL key cap functions start to work.

3. One of the XL key cap functions is always on / depressed. Using one of the two methods in this instruction, you will have to shorten the center spring using the spring shorting information at the early / beginning of this Best install article.

4. The Red LED in the bottom right hand corner of the XL Keyboard does not come on at all or is interment on and off when touched or typing on the XL keyboard. 1st check the small Phillip screw is fully tightened down on the back side of the metal plate directly under the LED socket. 2nd double check how the red LED is positioned into its LED holder. The LED flat indicating side on the bottom lip / ring of the LED should be facing toward the right. Many times on old XL keyboard with a LED problem, the LED has been removed reinserted back into the black LED socket 180 degrees off (flat side facing to the left) in an attempt to fix the non working LED and will not work at all. If this is not the problem, then fully remove the LED from its black socket. To clean the hidden internal leaf metal contacts inside the LED socket, take the 2 legs of the LED and insert and extract them about 10 to 15+ times into the LED socket. This should help scrap off any corrosion, rust or other foreign materials or coatings on the inside of the LED socket internal metal leaf contacts you cannot see. Next again remove the LED from it socket, with a piece of steel wool, clean the flat sides (front and back) of the LED metal legs of silver oxidation, corrosion and other foreign materials like, dust, rust, dried soda or moisture on the LED legs. If you still have LED non working problems, slowly remove and insert the LED legs into LED socket. If you do not feel resistance (the LED legs coming in contact with LED socket internal metal leaf contacts) on the LED legs as they are inserted into the LED socket, the LED legs are not making proper contact with the LED Internal metal leaf contacts. Remove the LED from it socket. Bend the left LED leg slightly forward toward you and the right leg slightly backward away from you. Now insert the LED legs back into its socket. You will now feel the LED legs making contact (insertion resistance) as you push the LED back into it socket. Once you get the red LED working properly, it would be a good idea to put some hot melt glue to lock the base of the LED to the black XL body LED socket. This will prevent the LED from flashing On / Off symptom that happens on very old XL Keyboards as you type on the XL Keyboard or getting knocked out of the LED socket by accident during reinstallation back into the XL top case.

Best Electronics in the Atari business since February 1, 1984.

Current Pacific Standard Time is:

E-Mail: