The story behind the making of the New Best CX40 Joystick Super inner Handle.

Atari CX40 inner Joystick Handles

Best knew that late in 2015 we are getting very low on the new replacement CX40 Joystick handles we got out of the local Sunnyvale Atari Parts warehouses about 12 to 14 years ago. Which would mean the end of the very very popular with all world wide Atari users, the Best CX40 Gold Rebuild kit (Best CX40 Lifetime CX40 Gold PCB board and stock Atari CX40 handle). Which turns an old failing Atari CX40 Joystick into a lifetime CX40 Gold Joystick. With no more CX40 joystick handles to be had anywhere, we knew we would have make the hard decision, Capital Investment and time to make a new CX40 Handle mold and have a new production run of them made.

Atari CX40 Handle History. The forerunner of the Atari 2600 bench mark CX40 2nd generation Joystick / inner handle design was the original Atari CX10 Joystick (shipped with very early 1st generation 6 switch 2600 Heavy consoles) that looks almost identical to the CX40 Joystick on the outside but with a completely different interface inner design.

Atari CX10 Joystick inner Actuator plate and inner Handle

The Atari CX10 Joystick had a completely different joystick handle interface (metal coiled springs on the bottom of the Joystick handle that fit onto 4 large round exposed studs) method that used 4 springs (about a ľ inch in diameter) on the bottom solid non flexing ring of the CX10 handle. The bottom of each spring would push directly into a white or black plastic actuator plate that had 5 flexible spring holding cups / arms, that in turn would push directly onto the top of unique CX10 PCB board (which are not interchangeable with the newer CX40 Joystick PCB boards) dome contact / mechanical mini switches. With nothing but constant in field / in use failure problems (actuator plate arms not properly pushing down on the CX10 PCB board dome contacts) on the original 6 switch 2600 consoles CX10 Joysticks, Atari quickly switched (within months after the release of the CX10 Joysticks) to the 2nd generation CX40 Joystick design (the bulk of Atari Joysticks produced in the last 30+ years).

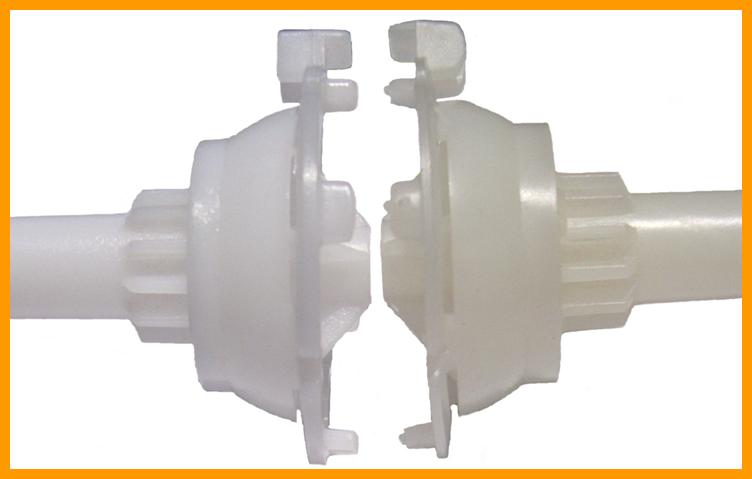

Left side: early 1979 - 1980 Atari CX40 joystick handle with thin but solid outer ring. Right side: last generation Atari CX40 handle with the four X and Y direction flexing bottom arms / lobes.

The Atari CX40 inner handle went thru many many Atari Engineering Rev. changes over a 20 to 25 year life cycle. But they can be grouped into 3 basic Atari CX40 joystick handle styles. The early 1980 CX40 handle with a very skinny / thin outer ring (left handle in picture above) which would easily fail / crack / break with the 4 small half diameter raised studs (on the thin outer ring) with small tits on the top of the stud that pushed directly on the top of the CX40 PCB dome contacts on CX40 inner PCB board. When one of these thin outer plastic ring would break, you would hear a clicking sound (from under the rubber boot) as you moved the Joystick handle you would lose some X / Y Joystick functions. A second version CX40 Atari Joystick handle with a beefed up / thicker solid outer ring will larger half diameter studs and with the small tits on top of the 4 studs again. The last and final CX40 handle revision change Atari Engineering made was a New / Final generation CX40 Handle with 4 flexible arms / lobes (above right side picture) with larger half round studs with again small dome contact small tits.

Over the decades the Atari CX40 Handle colors ranged from early Jet-black handle, white and translucent colors. Atari Engineering used several different plastic materials / compounds over the years.

Ask any old Atari CX40 Owner how many early CX40 Joysticks (handles with the thin outer ring) they broke and tried repaired / replaced broken handles over and over for years and years. Atari put out thru their Atari Original Equipment Manufacture replacement parts series carded replacement CX40 PCB boards, Joystick rebuild kits with 2 rubber boots, 2 boot rings, 2 PCB's and 2 fire button springs on one card thru their Atari Authorized Dealers. This supported Atari CX40 users, but really never cured all of the different CX40 Joystick problems. Best knows the main reason why all of the CX40 handles / Joysticks always failed early. It came down to the quality of the early generation weaker Phenolic PCB maternal (before the stronger now Electronics Industry standard Glass Epoxy PCB material ) CX40 Joystick inner PCB boards. As the CX40 PCB dome contacts (5 contacts) failed (Atari Engineering rated the CX40 inner PCB dome contacts at 1,000,000 cycles / use before failure, but Bests CX40 Gold Lifetime PCB manufacture ran tests and found a brand new stock OEM CX40 PCB board (last generation made) contacts would start to fail at about 150,000 use cycles) the Atari CX40 joystick user would put more pressure and over pressure on the CX40 inner handle, so it would make the failing dome contacts make the proper electrical contact, which would over stress the thin outer ring on the CX40 handles and cause them to alway fail early.

Best has cured the CX40 under performing Atari OEM stock CX40 Joystick PCBís with our Best exclusive designed 2005 all Gold lifetime CX40 board, which is now in its 4th Rev. / 4th Generation.

Best considers an Atari

CX40 Joystick inner handle equivalent to tires or a battery on a Car. Basically

a wear and tare type of item that has to eventually be replaced with years of

use. New car tries are Designed / Engineered / Warranted to last so long (so

many miles / months / years of use) and then be replaced with brand new ones. There are

expensive new tires costing $$$+ and used ones $$ or less. So if you put brand

New tires costing $$$+ dollars each on a used car that has damaged / worn out

front end suspension or misaligned or damaged rear end suspension, the New

expensive / high performance tires will wear out fast. The equivalent in the

Atari world, would be to put one of Best New Upgraded / Enhanced / Beefed up

Super CX40 handles into an old Atari CX40 Joystick with a stock Atari made

always failing internal CX40 PCB board. It would be possible to even ware out

one of the new Best 2018 CX40 Super Handles

eventually. With the always failing stock Atari

CX40 PCB board and Best Super CX40 inner handle, you will

still put more and more over

pressure on the Best CX40 Super

inner handle to get the stock always failing CX40 PCB dome contacts to work

properly. Even if you did install the New Best CX40 Super handle into an

old Atari CX40 Joystick with the failing PCB board, with all of New Best Engineering

changes below, the Best CX40 Super handle should still last 3X to 10X times longer

with everyday / years of use compared to the stock Atari Engineering CX40 handle

design. But if you installed one of Best 2018 CX40

Super Handles

with Bestís CX40 Lifetime

Gold

internal PCB board and Bests 2016

Lifetime Silicon CX40 Joystick boot into an old Atari CX40 Joystick, then you can call the Best

Super

CX40 handle a Lifetime

CX40 handle. So we have

named the

New 2018

Best CX40 handle with its thicker / reinforced bottom flexing ring, Improved / Upgraded /

Larger dome

contact 4 studs, 20 New radiuses strain relief

Best Electronics has known over the years why all of the different Atari Engineered CX40 handle versions / revisions failed over the last 25+ years. With Best Electronics background (at a local Silicon Valley Plastics Injection Molding company that made millions and millions of Atari plastic parts for Atari at the height of the Video game craze) in the Plastic Injection molding industry, we know we could Engineer / Redesign an Improved / Upgraded 2018 designed Atari CX40 Super Handle. Combined with the Best CX40 Gold Lifetime PCB board, the 2016 Best released Lifetime Silicon CX40 Boot would turn any new, old, used failing Atari CX40 Joystick into a lifetime Atari Joystick with newer technology that was simply not available when Atari Engineering 1st designed the Atari CX40 Joystick in the early1980ís.

Unlike the 17+ Month (was a Company record for that time, until the CX40 Super Handle 30 month project) recent search to find a New Best CX30 Super pot vendor (in a shrinking world wide Pot Manufactures pool), the search for a new CX40 Plastic handle Injection molding vendor was a lot easier to find one. It came down to the sorting thru 20 to 30 Plastic Injection molders who contacted Best.

Jeremey Z. of WI On his very 1st Atari order to Best, Jeremey ordered a Best CX40 Joystick Gold Rebuild kit (Rev. 4 Best Gold CX40 Lifetime internal PCB board and Best designed CX40 Super handle) and a new Best Designed / Upgraded Atari CX40 Joystick Silicon Joystick boot. A Best designed 2nd Gen. Upgraded / Enhanced XL replacement keyboard mylar to repair his ailing Atari XL computer Keyboard. The final Best upgraded Atari part Jeremey got from Best was a set of replacement CX30-S5 Super Pots to fix his old Atari CX30 Paddles that had cursors that were jumping all over the game screen during normal Atari Paddle game play. "I just wanted to send you a quick email saying holy cow, that was FAST. I didn't expect the package to show up until later this week, it was on my front step yesterday afternoon. The Joystick is 100% better, the new joystick handle feels even better with the new grip and stick, I'm thoroughly impressed. The keyboard mylar was also way easier to install than I thought, Lined it up with the keyboard and just screwed it in no problem. The paddle pots solved the problem with flying ALL over the screen and they're like new again. Thanks again for all your help and support! I'll definitely be coming back for more parts in the future!"

John H. of WA. John ordered two Best Atari CX40 Joystick Gold rebuild kits (2, 4th Gen. Best designed CX40 Gold PCB boards and 2 Bests designed Atari CX40 Super handles) and 2 Best designed new 7 foot CX40 Upgraded Gold Joystick cables. "Wow what an improvement! I put the CX40 upgrades in last night and they are amazing! Thanks for keeping the Atari spirit going!"

Murray M. of TX Murray ordered 3 complete Best CX40 Joysticks upgraded with Bests Gold lifetime CX40 PCB board, Best designed new CX40 Super handles, new Bests CX40 lifetime Silicon boots and an extra Gold lifetime CX40 PCB board "I just received my shipment yesterday and first off, I have no idea how you got this to me so fast. No other seller of anything in the past few months has been able to get anything to me, priority mail or otherwise, so quickly. Thanks for acting so quickly! Now for the real feedback: Wow this rebuilt stick feels good. Really good. Unfortunately I've never played on a brand new CX40 so I don't have that as a frame of reference but I have played on a NOS Gemstik (just as squishy and sloppy as my dead CX40s) and a CX40 rebuilt with some PCBs from eBay that use some super tiny tactile switches instead of metal domes (very good at first but fell apart after about 2h play time)" Best has seen these new black replacement CX40 PCB boards on E-Bay and they sell for more money than the Best designed 2005 Gold CX40 PCB boards. The E-Bay seller claims the tiny micro switches are rated at 1 million cycles. The Best over sized 4 leg Gold plated Dome contacts are rated at 5 Million cycles. "and this beats both hands-down. Everything about your CX40-GSHSB stick, from the feel of the boot (Bests new CX40 lifetime Silicone boot) to the responsiveness of the buttons and directions just screams quality. At this point I'm just a little bit regretful that I didn't get the silicone boot and new wiring for the sticks I'm repairing but hopefully I'll be able to do another order in the near future for that. :) Thanks for making such great products!

John D. of CA John ordered 2 new Best CX40 Joysticks upgraded with the Best designed CX40 Gold lifetime inner PCB board, Best designed new CX40 lifetime Silicon Joystick boot, Best designed / Upgraded CX40 inner Super Handle, and just released Best designed Upgraded / Enhanced CX40 Gold 7 ft (stock CX40 cable is only 4 ft) Joystick cable. Basically the Best of the Best upgraded CX40 Joystick Bests sells. "Thank you for the Joysticks!!!! They rock! Even my 17 year old had fun!!!"

Just for your Atari Information, when Atari made any of the 4 to 8 cavity CX40 Plastic handle Injection molds (Best Estimates they made at least 4 to 6 different new CX40 Handle molds over the total life cycle of the CX40 Joystick) the ball park cost for each of these new hard steel tooling (long life molds, that would make millions and millions of CX40 Handles) back then (1980 to 1990 era), cost Atari around $25K to $35K+ per New CX40 Handle mold, a lot of money for that 1980ís time frame / era. Early in 2016 Best put a 50% non refundable deposit down on a new Atari Joystick handle mold. Balance of New Joystick handle mold cost, due when the final new CX40 handle samples were approved by Best. During the 30 month New Atari Joystick project, Best had to make several more payments to the Injection Molder, for handle design / mold changes / Best design upgrades, 6 different sample production runs (1st article samples) off the modified Joystick Handle mold. When the new Best Super Joystick handle was finally approved by Best, another final payment was made to Injection molder, for the actual 1st production of the New Best Super handles and shipping costs to ship the Best CX40 Handles to our San Jose Atari warehouse.

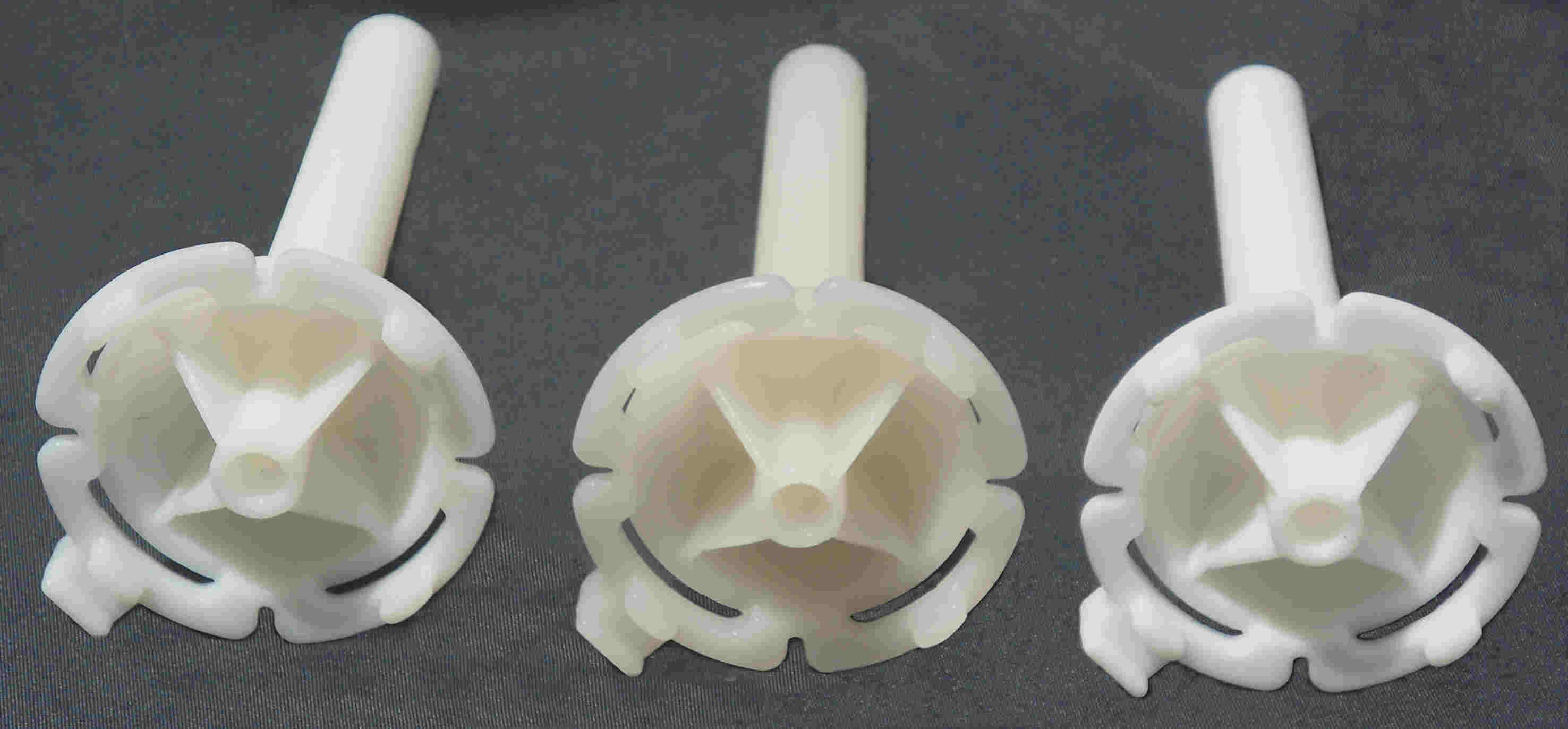

First article sample Joystick handles off the New Best 2016 plastic injection mold. The New Injection molder finally went with an ABS plastic material which is a lot stronger / harder plastic compound for the new Best CX40 Super handle. The color difference is two different ABS plastic compounds used on the samples.

New Best CX40 Super Last Gen. Atari CX40 Close up view

handle handle

The above close up pictures shows a few of the New features of the Best CX40 Super handle. Contact area where the 4 arms attached to the CX40 round bell shaped base have been beefed up with a wider / stronger (one of the areas the old CX40 handles would always fail) contact surface area to the base handle dome area. Over 20 sharp edges / corners / locations (areas where the stock Atari CX40 Joysticks would always show the white stress marks in the plastic and eventually crack / break in these areas) on all of the old Atari CX40 handles, have been radiuses / rounded on the Best Super Joystick base area for better strain relief flexing. Any plastic Engineer will tell you, sharp plastic molded in corners / right angles, under repeated stress in a flexing area, will be where a plastic molded part will always fail early. In the above close up picture above (right picture), notice that the Best CX40 good radiuses surfaces where the handle arm are attaches to the handle base. The right side stock Atari handle arm has a lot of very sharp edges where with the outer arms (U shaped cavity) attaches to handle base cone.

New Best CX40 Super handle Last Gen. Atari CX40 handle

One of the very common areas on the stock made Atari CX40 Joystick handles, that always fails / cracks / breaks almost 100% of the time, is the thin outer round ring (12 Noon to 6 PM area in above picture) around the bottom of the Joystick handle. Notice the increased / beefed up thickness (almost double) of the outer ring / 4 arms on the Best CX40 Super handle that supports the 4 dome contact raised studs, vs the very thin outer ring on all of the stock Atari CX40 handle (see right handle in above picture) made.

Bottom close up view of the Best New CX40 Super handle dome contact larger rounded edges rectangular stud (left handle in the right picture) and stock Atari black CX40 handle with the small half round stud with dome contact small round tit (right black handle picture)

Best has known for years, that this small raised tit (on top of the 4 half round raised X / Y studs) on the stock Atari CX40 handle outer ring was one of the many many reasons why the center dimpled metal dome contacts on the old Atari CX40 PCB boards would invert (go from a concave shaped dome contact to a failed inverted convex dome contact, as the clear tape covering over the dome contact would fail / pull away / off the dome contact). When the small round tit on the stock CX40 handle was pushed down of the top center of the dimpled (half round, round or triangular shaped dome contacts used on the years), with enough force or over pressure (because of the stock Atari CX40 inner PCB board failing shaped dome contacts) was applied to a very small dimple area on the top of the Dome contact, it would cause it to fail / turn inside out on the top of stock Atari CX40 Internal PCB board.

Instead of the Atari CX40 handle raised small tit on a half round stud design on the outer joystick bottom ring (see above right picture) used on just about all of the Atari CX40 handles made over the years, Best went with a longer length / wider rectangular shaped dome contact stud with rounded edges, (with no tit on top) to greatly increase the contact area approximately 5X to 6X increased rectangular top stud surface area to dome contact top surface area (based on a mathematical average of the 16 different sample stock CX40 handles tit diameters made in over a 25+ year period) on the mating metal dome contact top surface area on the CX40 PCB board. This also increases the (on the Best made CX40 Gold PCB board) inside Gold plated metal dome contact electrical surface area that is pressed against the mating circuit CX40 PCB Gold plated contact trace area under the dome contact.

Best ran all kinds of tests on the new 1st article CX40 Super handles and found many problems with them that had to be corrected. In an effort to make a CX40 Handle that would never fail, the Plastic Molder went with new harder Acrylonitrile Butadiene Styrene (ABS) plastic molding compound. The problem with these CX40 1st article sample handles was they were the very stiff (4 bottom arms / lobes did not flex at all). When one was installed into a stock CX40 Joystick, after you used them for any length of time, your hands would fatigue very fast. On all of the different version Atari CX40 handle designs over the last 25+ years, they had one good thing in common. The 1st generation thin and 2nd generation wider outer rings versions and the final generation 4 lobes / arms Atari designed handles bottom rings all flexed to some degree when they come in contact the inner CX40 PCB dome contact top surfaces and came to a soft X / Y stop. So when you moved the stock Atari CX40 Handle in any X / Y direction, the bottom of the Joystick handle ring with the stud would push on the CX40 internal PCB board dome contact (make the switch contact / circuit) and the CX40 handle would still flex or over flex just a little, to gave that Joystick handle direction a soft direction stop. With the very stiff / hard 1st article sample Best CX40 Super handles, Best knows that your joystick handle hand with start to fatigue very fast because of the very hard / stiff X / Y direction stops with no give. It would like jumping up and down on soft bed vs jumping up and down on a sold cement floor. You can jump and down on the soft bed for hours with no problem, but jumping up and down on a cement floor you could not do for very long without fatiguing your legs. Although that stiff CX40 handle would last the average Atari CX40 Joystick user 5X to 6X lifetimeís worth of normal use, the Joystick hand fatigue was simply was not worth it. We asked the Plastic Molder to switch to softer plastic molding material.

The second major problem on the 1st articles samples, when the handle was inserted into the upside down CX40 top case opening (without the CX40 boot installed), the handles had to much X / Y free drift (handle rattled inside the CX40 top case Joystick handle opening. Best knew that this loose fitting 1st Article Joystick handle into the Top joystick top case opening hole would cause, X / Y studs (on the bottom of the joystick ring) to miss aliment over the center of the dome contacts on the CX40 PCB board. All of the different versions of the stock Atari CX40 handle made over all of the years, always fit snugly into the top CX40 top case inside Joystick handle opening. So the 4 half round studs on the bottom of the CX40 handle ring were always in perfect aligned over each of the top dead centers of the X / Y 4 dome contacts on the CX40 PCB board.

All of the 1st,and 2nd article New CX40 Handle samples Best received, all had two problems which our new Injection molded could Not seem to cure. When the new CX40 Handles were installed into a stock Atari CX40 Joystick with Best CX40 Gold Lifetime PCB board, the Joystick handle was moved in a X / Y directions, there was no dome contact Click sound with the Tactical click and bounce back feel thru the CX40 handle. Which is one of the upgrade features all Atari CX40 Joystick Owners love about the Best CX40 Gold PCB boards with the stock Atari made CX40 Handles. On the 2nd article samples our new Plastic molder sent Best, they even took some of sample handles and hand ground down the thicker outer ring thickness back to the original Atari CX41stin outer ring. Another group of 2nd article handles they hand ground down the 4 rectangular dome contact top of the studs in half and a different set of handles they ground down the rectangular dome contact stud down to a thin sharp edge. None of these attempted changes to the new CX40 handle our plastic molder did, corrected the Dome contact click sound problem. We are talking about several months of different attempted changes to the new Best CX40 handles, the molder still could not correct this lack of dome contact click problem.

3rd article sample Clear ABS CX40 Handle

After the 3rd article sample clear CX40 Handles (a different formulation of ABS plastic molding compound) were sent to Best, the plastic molder still had the same No dome contact tactical feed back / click sound problem and the new plastic molders Engineers could not fix this problem. Both the Plastic Injection molder and Best was getting to the point of giving up on correcting this critical problem and possibly scraping the new CX40 Handle mold / project totally. As a last resort, Best did an in depth week long study of this problem. Best finally found two dimension problems that the Molder Plastic engineers missed all of the months and months they studied this problem. Best suggested that the plastic injection molder make changes (another $$$ cost to Best) to the new mold to correct this problem and send Best some 4th article samples handles.

One of the problems over the months and months of working on the new Best CX40 Super handle, was the Plastic molder was sticking with the harder ABS plastic molding compound, despite the many many times Best requests for them to switch to a softer plastic molding compound.

After months and months of back and forth with the New Plastic molder, Best finally convinced the new plastic molder to go back the original Atari CX40 softer Poly Propylene plastic molding compound, so we could get the 4 plastic arms on the CX40 Bottom ring to flex / give just a little when the CX40 Super handle reached it full X or Y travel range.

About ĺ thru October 2016, Best finally got some Good News from our plastic Injection molder. They modified the new CX40 Handle mold with the dimension changes Best asked them to modify. Then they molded some new 4th article sample CX40 Super Handles. When installed into a stock Atari CX40 Joystick (at the plastic molder factory) with a Best CX40 Gold Lifetime PCB, now finally got the dome contact click / tactical feed back on the X and Y CX40 handle movements (they sent Best a video of these tests, before sending us any 4th article samples), that had been missing for months and months earlier sample CX40 handles.

So it finally came down to the Injection Molder sending Best, 3 different polypropylene formulations of 4th article sample CX40 handles they had molded, to run our final CX40 flex and long life tests on.

Close to the last week in October 2016, Best received the 4th article samples of the Best CX40 Super Handles from our Injection Molder. Best verified that the CX40 Best Gold PCB board Dome contact click problem was finally fixed. But the 3 different formulations of the Polypropylene plastic compounds sample CX40 handles were still on the stiff side. A little more flexible that the ABS plastic CX40 Handle samples but still far to stiff from what Best wanted. So we told the plastic injection molder, that we still required much softer feeling Polypropylene material, so the 4 arms on the bottom of the CX40 Super handle will flex and give the a soft / cushioned direction stop when the CX40 handle is moved in any X or Y directions.

The second week in December 2016, Best got the word from our plastic Injection molder that they found a New Hybrid (Polypropylene (PP), Polyethylene (PE)) plastic mix molding compound, that would meet Bests long life requirements for the CX40 Super Handle, a clear plastic molding compound and would also allow the 4 bottom arms / lobes on the bottom of the CX40 Super handle to flex during normal use. The molder said this Hybrid plastic compound has been used in several different new plastic parts which now have a proven track record. They even sent a MP4 video, showing how much the bottom arms of the new Hybrid plastic CX40 Super Joystick handle flexed. So Best requested some new 5th article samples to run some long life flexure tests on the new Joystick handle material.

Top View, 5th article sample Best CX40 Super

Handle with Best Web site address and Atari Part number

Engraved into the mold / CX40 Super Handle.

End of December 2016, Best received 5th article samples of the Hybrid plastic material CX40 Super handles. Our plastic Molder supplied Best 2 different plastic formulations of the Hybrid plastic handle CX40 handle samples. For the 1st time in the last 9 months of sample CX40 handles, both plastic formulations of the 5th article samples handles, the bottom 4 arms on the handles flexed to the degree that they were equivalent to the last version CX40 handles Atari made. Our plastic molder finally meet one of the absolute must have Engineering standards Best required on the new CX40 Super handles. The all new Hybrid CX40 handles were now put thru long life cycle testes using several last generation Atari made CX40 handle as a bench mark standard to run comparison long life cycle tests on.

About a day into the continues long life cycle tests, one of the Hybrid CX40 plastic handle hybrid materials starting to show signs of failure (minor white stress marks and cracks in the flexible arms) and quickly failed long life cycle tests. A few days later of continuous cycle tests the standard last generation Atari CX40 handle started to fail in the same areas. The other formulation of the CX40 Hybrid plastic material went more days of continuous long life cycle tests (after the stock Atari CX40 handles failed) but also started to show signs of failure in the bottom flexing arms.

So Best sent a test report back to our Plastic Molder saying that one (1st sample) of the Hybrid plastic sample handle material did not meet or match the performance of the last generation of Atari CX40 handle. The second formulation of the Hybrid plastic molding material was big improvement of total cycle life (compared to the last generation CX40 handle), but still did not meet Best longer life cycle test requirements for the new CX40 Super handle. We suggested to our Plastic molder that they change the PP / PE Hybrid plastic compound mix ratio away from the 1st sample hybrid molding compound and a couple steps above the 2nd Hybrid sample handles. Best requested some new sample handles in the reformulated Hybrid plastic compounds.

Mid March 2017, the plastic molder said they had runs some new test shots using three different plastic molding materials. They said they were not happy will results and had to order some new plastic molding compounds to run new test shots with. On March 28, 2017 Best received New 6th article samples of the Best CX40 Super Handles. Our plastic injection molder did a major change / direction in the plastic molding compound formulation used on the latest samples of the Best CX40 Super handles. They sent Best 3 different formulations of a low density Polypropylene CX40 Super handle samples. Right out of the samples bags, these new sample Best CX40 Super handles initially looked and functioned (4 bottom floating lobes on CX40 new sample handles) flexed (like the stock Atari CX40 Joystick handles) just exactly what Best was looking for in an improved Atari CX40 Joystick handle. It now came down to see how the 6th article new samples Super handles would function in long term extended life cycle testing and several other CX40 function tests.

As part of the final tests Best did on the latest 6th article sample Super Handles samples, we sent up three identical Atari CX40 Joysticks with Bests CX40 3rd Generation Gold Lifetime Internal PCB board installed in both Joysticks and the new 2016 Best CX40 Lifetime Silicon Joystick boots. One Atari CX40 Joystick had the last Revision CX40 Joystick handle with the 4 lobes on the bottom ring and the other identical Atari CX40 Joystick with the Best 6th article sample of the CX40 Super handle inside. 8 out 9 blindfolded CX40 Joystick testers could not tell the difference between the two CX40 Joysticks during normal Atari game play. So that means that the new 2017 Best CX40 Super Joystick handle with all of its Life extending Upgrades and Improvements, like the thicker bottom ring with larger wider contact area to the bottom of the CX40 handle bottom cup shaped surface, 4 larger dome contact studs, 20 radiuses and rounded corners and improved plastic molding compound, did not effect the basic Atari CX40 Joystick handle functions and features compared to the last Revision 4 lobed CX40 Joystick handle Atari Engineering made.

A week into the continues testing of the new 6th article samples of the three different formulations of the low density Polypropylene CX40 Super handle samples, we could see a major improvement. Two of the new low density Polypropylene CX40 Super Handle formulations out preformed any CX40 sample handles we have received in the last 4 months. The third Rejected sample low density Polypropylene molded Super CX40 Handles started to show signs of early failure. A couple of these rejected CX40 Super Handles cracked on the thicker bottom Joystick bottom ring during long term cycle testing, but the CX40 Test Joystick still tested good. All you could hear during the long cycle time tests, was a second minor dome contact click (cracked ring flexing) in the direction the bottom Joystick ring cracked. Because of the beefed up thicker bottom CX40 Joystick ring, the cracked bottom ring acted like a normal fully working CX40 Super Handle.

After a couple of weeks of long life continues cycle tests, close up magnifications of the improved 2 CX40 Super handle plastic formulations, still showed some minor white stress marks on the bottom ring and some minor cracks in the bottom Joystick bottom ring area. We sent back an early 6th article receiving report (with photos) back to our Plastic molder on the latest test results. Based on this new test results, we asked our plastic molder to find some other low density Polypropylene formulations that would correct these last minor problems. On April 9, 2017 our Plastic molder said they reviewed our test report with photos and did some more research. They said they found 2 higher grade LDPE plastic molding compounds that should fix the minor cracking problem on the bottom of the joystick ring. But of course the two new molding compounds are more expensive than any of the plastic molding compounds they have used to date.

With the new test shots of two latest new plastic molding materials, of course would mean another $$$ set up charge (hanging of the new mold in the Plastic Injection molding machine again) and sample charge for the bags of new test molding compounds, new test shots (handle samples) and the cost of shipping them to Best. Like all of the other past Joystick handle test shots, they had to be paid up front again, before the samples could be shot / molded. On April 13, 2017 Best sent the funds to the plastic molder for the new test shots. On May 2, 2017 Best received the 7th article samples of the Best CX40 Super handles and started to long term extended cycle testing of them.

On May 11, 2017 after 9 days of continues cycle testing of the new 7th article sample handles everything seemed to be going well on both of the new molding compounds. All X / Y Joystick / Atari game functions were functioning fine. But when we opened up the all the functioning CX40 Joystick samples, we received a big surprise. Both the new handles of both new molding compounds had cracks (but not completely open cracks) in the outer joystick thicker bottom rings. A little more on one new Molding compound and less on the other. But on both of the different CX40 Super handles test samples, the X / Y CX40 PCB board dome contacts still worked fine. On the stock made Atari CX40 handles when the thin bottom ring, any cracks on this very thin outer ring, meant the CX40 dome contact near that crack just stopped working (not properly actuate / press on the CX40 PCB dome contact) and usually you would hear / feel a clicking sound (as the broken parts of the outer ring would flex / rub against each other) coming from the inside of the CX40 Joystick during normal use / play. To Best this latest 7th article CX40 Joystick handle early test results, meant the Redesigned and Upgrades on the Best CX40 Super Handles, were a Fault Tolerant Engineering design, they keep working fine, even with cracks in the outer joystick bottom ring. All that was needed to finally put this Best CX40 Super handle project to bed, was to find the right new plastic molding compound that would not crack with any normal use / play.

So another 7th article sample receiving report was sent to our plastic molder. The main suggestion Best sent to the plastic molder, was to check the plastic compound used on the different Atari OEM CX40 handles we sent them a year+ ago and see of they could match or find a newer generation of that plastic molding compound for the Best CX40 Super Handles.

Late May 2017 early June 2017, we started to have commutation problems with our Plastic Injection Molder. E-Mails were not being returned to Best. We came to the conclusion that this plastic molding vendor had given up trying to find the right plastic injection molding compound to make the Best CX40 Super Handles. So the for the very 1st time in 38 years in the Atari business, we had to drop the current Plastic Injection Molder and start looking for a new Plastic Injection molder to take over this project. In the meantime, Best filed a dispute with the Injection molder which to this date, has not been settled.

Best knew finding a new Plastic Injection Molder to take over our Best CX40 Super Handle project was not going to be an easy task. Most Injection molder companies are reluctant to take over a new plastic product from another Injection molder. So searching thru 15 to 20+ new Injection molders for the next two months, Best convinced a new Plastic Injection Molding company that the new Best CX40 Super CX40 Handle Mold / CX40 handle was a proven approved design and it was simply a matter of finding the right Plastic Molding compound to make the new CX40 handles.

So late September 2017 our new Injection molder had picked up the new Best CX40 Super handle mold and sample old CX40 Joysticks and old Atari CX40 handles we sent to the 1st Injection molder, old from the 1st Injection molder. They were ready to run some new sample plastic molding compounds thru the mold. Again Best sent funds $$$ to the new Injection molder for the new plastic handle samples and shipping costs to Best.

Although Best fully explained to the new Injection Molder all of the problems we had with the last CX40 handle samples from the old Injection molder, the 3 new molding compounds CX40 sample handles Best received the second week of September 2017 were totally not useable at all. It was like taking a 10 month back step and starting all over with the new Injection molder.

After months and months of communications back and forth with the New Injection molder, they said they found a new plastic molding compound. Again Best sent funds $$$ to the New Injection Molder for a second set of sample handles and shipping costs to Best.

The 1st week of December 2017, Best received the latest CX40 Super handle samples. The new CX40 Super Handle samples fixed one of the problems on the 1st article handles had from our new Injection molder. It again give the CX40 Done contact click sound on the CX40 internal PCB board. But the second problem on the 1st article sample handles was improved, the flexing of the 4 bottom arms on the CX40 handles. But was still to stiff to meet Bests requirements. In theory these stiff CX40 handles would last the average CX40 a lifetimes worth of normal use, but because of the stiffness (hard stop vs a soft stop) of the CX40 bottom arms, the CX40 Joystick user hands would get very tired very fast with any normal use. Best sent this little flexing information problem back to our New Injection molder to help them find a softer plastic molding compound to fix this very last problem with Best CX40 Super handles.

On January 08, 2018 our New / 2nd Injection molder E-Mailed Best and said they found two plastic molding compounds that should meet all of our Atari CX40 Super Handle requirements. So on January 10, 2018 Best sent another payment $$$ to our Plastic Injection molder from another test shot of both of the new plastic molding compounds and shipping of those new samples to Best. On February 2, 2018 Best received the latest sample Joystick handle samples. It ended up we only received a single type of new molding compound sample CX30 handles. Again, the new sample molding compound was again to stiff and did not allow the new Best CX40 Super handle 4 bottom arms to flex up and down. Again, the latest new stiff sample Joystick handle would last the average Atari CX40 Joystick user a lifetimes worth of normal use. But because of the stiffness of the CX40 handle, your hands would get very tired / fatigued very fast because of the stiff / non flexing CX40 Joystick bottom arms. Two different plastic Injection molders and Best could not get this CX40 plastic handle bottom arms flexing requirement across to them.

On February 23, 2018 our Injection molder said again the are sending two more different plastic molding compound Joystick handle samples to Best.

Early March 2018, we had received another 2 sets of different new molding compounds CX40 Super handle samples to test. It was becoming clear to Best, this second new Plastic Injection molder had fallen into the same sample mode that the 1st Plastic Injection molder did. Not listening to our requirements for a Best CX40 Super Handle that the bottom 4 arms flex during use. Best had to make a hard decision to settle with the sample CX40 handles we had received so far, which we do not like because their stiff non flexing bottom arms or for the 1st time in the last 39+ years in the Atari business, walk away from the CX40 Super Handle project and scrap the new CX40 mold.

After some deep soul searching thinking, Best decided on a third option. Walk away from the Best CX40 Super Handle project for a couple of months and then take a fresh perspective / approach down line. Middle of May 2018 we decided that we must approach the New Plastic Injection molders a completely different way / method to find the one that would work with us. For the third time, we put out a request for a new Injection Molder for our CX40 Super handle project. Again another 18 to 20+ New Plastic Injection Molders contacted Best. We sent all of them, a new set of requirements for the Super Joystick handle. Out of all of those New Injection Molders, only one contacted Best and by their responses to our E-Mails, Best felt that they could meet our requirements. They said their Plastic Molding compound Engineer found 3 new flexible Plastic Molding compounds that should meet our flexing requirements, but they required the New Joystick mold to proceed.

To date, Best had already spent over $,$$$+ (this amount does not include the cost of the New Injection Mold ($,$$$+) and the thousands and thousands of Man hours spent on this Super Handle project so far) on CX40 handles samples, sample shipping charges and the cost to have the New mold shipped to 2 different injection molders, without receiving a single CX40 Super Joystick handle that would meet all of Best requirements.

On May 21,

2018, our new 3rd Plastic Injection molder contacted Best saying they were

having problems with the 2nd Injection molder releasing /

On May 31, Best got the word from the 3rd New Plastic Injection molder, the 2nd Injection molder finally shipped the mold and they had already received it. They said it will take about 10+ days to order and receive the 3 new sample plastic molding compounds and find a open slot in their Injection molding machines production schedules (most good Injection molding companies, usually work 5 to 7 days a week, 2 to 3 shifts per day, doing nothing but molding plastic Injection molded plastic parts) to run the CX40 Super Handle samples.

On June 10, 2018 Best received an E-Mail from our 3rd plastic injection molder that they had 5 (instead of the 3 Best paid them for) different molding compound samples of the Best CX40 Super Handles ready to send to us. The said at least 2 of the new plastic molding compounds should meet Bests requirement for the bottom ring of the new Best CX40 handle to flex up and down. They even sent Best pictures of the bottom ring of the CX40 Super handle flexing up and down.

On June 15,

2018 our New Injection molder said they received Bests payment to them for the

sample shipping charges. They shipped the 5 New sample molding compounds

super handles to Best the same day.

On June 19, 2018 Best received the 5 new 1st article sample batches of CX40 Super handles. We put them in long term testing cycle. About 2 days of the continually cycle testing some initial tests results started to show up. 4 of the new sample joystick handles were simply too stiff and would not flex on the joystick bottom ring. One of the very stiff Joystick handles started to show white stress marks (precursor to cracking / breaking) all over the bottom Joystick ring but the other 3 samples did not show as much or very little white stress marks. See CX40 Handle picture below.

Contrast and

Brightness levels have been adjusted on this rejected Best CX40 Super Joystick sample

Old Atari CX40 Joystick owners have seen these same white stress marks on a very old and well used stock Atari CX40 Joystick handle bottom very thin rings just before the bottom joystick ring cracked / broke.

But one new sample handle did flex on the bottom ring. After several more days of continual testing we noticed same minor white stress marks on the bottom ring of the one promising flexing Joystick sample handle. Also we noticed a major crack in several of the bottom joystick ring studs. Examing the same lot of one of the untested flexible joystick rings, under a microscope, we noticed a knit line in the plastic Joystick bottom ring exactly in the same exact area where the joystick stud started to crack in half. A knit line, is a plastic Injection molding term, that means when the very hot injected plastic molding material is injected into a closed mold like into a ring shape, one of the paths of the hot injected molding material is heading / flowing in a clock wise direction around the ring and the other path of the hot molding compound is heading into the ring counter clock wise. Where they meet is a knit line location. Plastic Injection molders have many ways (control how fast the hot plastic is injected into the mold, Mold temperature, cycle time, how long the hot plastic molded part is left inside the mold before it is ejected out of the mold and many more techniques) they can control how well the two hot molding blend together if they know about a cold knit line problem. A cold knit line in plastic molded parts look perfectly fine / good under normal visual inspection, but under normal working conditions like the flexing Joystick bottom ring over years of use / time, will fail or crack eventually.

On June 22, 2018, Best sent a primary 1st article receiving report back to our new Injection molder with about 8 to 10+ pictures of the problems we have found on the 5 different molding compound sample handles so far. A half day latter their Plastic compound molding Engineer got back to Best with some suggestions to correct the sample Joystick handle problems.

A few Best rejected (redesign

the Joystick bottom ring so it no longer had a floating ring but was a solid piece of the

Joystick bottom bell shape) a few we agreed they can try on the next run of

sample Joystick handles. Another suggestion they made was to get away

from the original Atari Joystick handle plastic molding compound / material (that was

State of the Art plastic molding compound Atari used back 35+ years ago) to a

newer plastic molding compound. So for the 4th or 5th time during this 28

month Best CX40 Super handle project, Best agreed to a new plastic molding

material change. Best has always known that a new plastic Injection mold designed for one type

plastic molding compound / family of plastic molding compounds (with their different shrinkage rates, flow rates within the mold

and other plastic material properties during the injection molding process) can possibly cause a whole new set of

possible injection molded part problems, some of which would require physical

modification / tooling change to the new Best CX40 Super Handle mold to get a

proper working Joystick Handle.

Another gamble and cost to Best.

On July 9, 2018 Best received the 3 new CX40 Super handle / molding compound samples. Right off, 2 of the 3 sample plastic molding compounds / sample handles were simply too stiff (did not flex on the bottom joystick ring) and were rejected without running any extended life cycle testing on them. We did notice that on all 3 molding compound CX40 Super Handle samples, our new Injection molder had fixed / cured the knit line problem on the bottom of the CX40 Super Handle bottom ring on all of the CX40 samples submitted. The 3rd New molding compound / CX40 Super Handle samples flexed on the bottom Joystick ring. They looked very promising and were put into long life cycle / game testing.

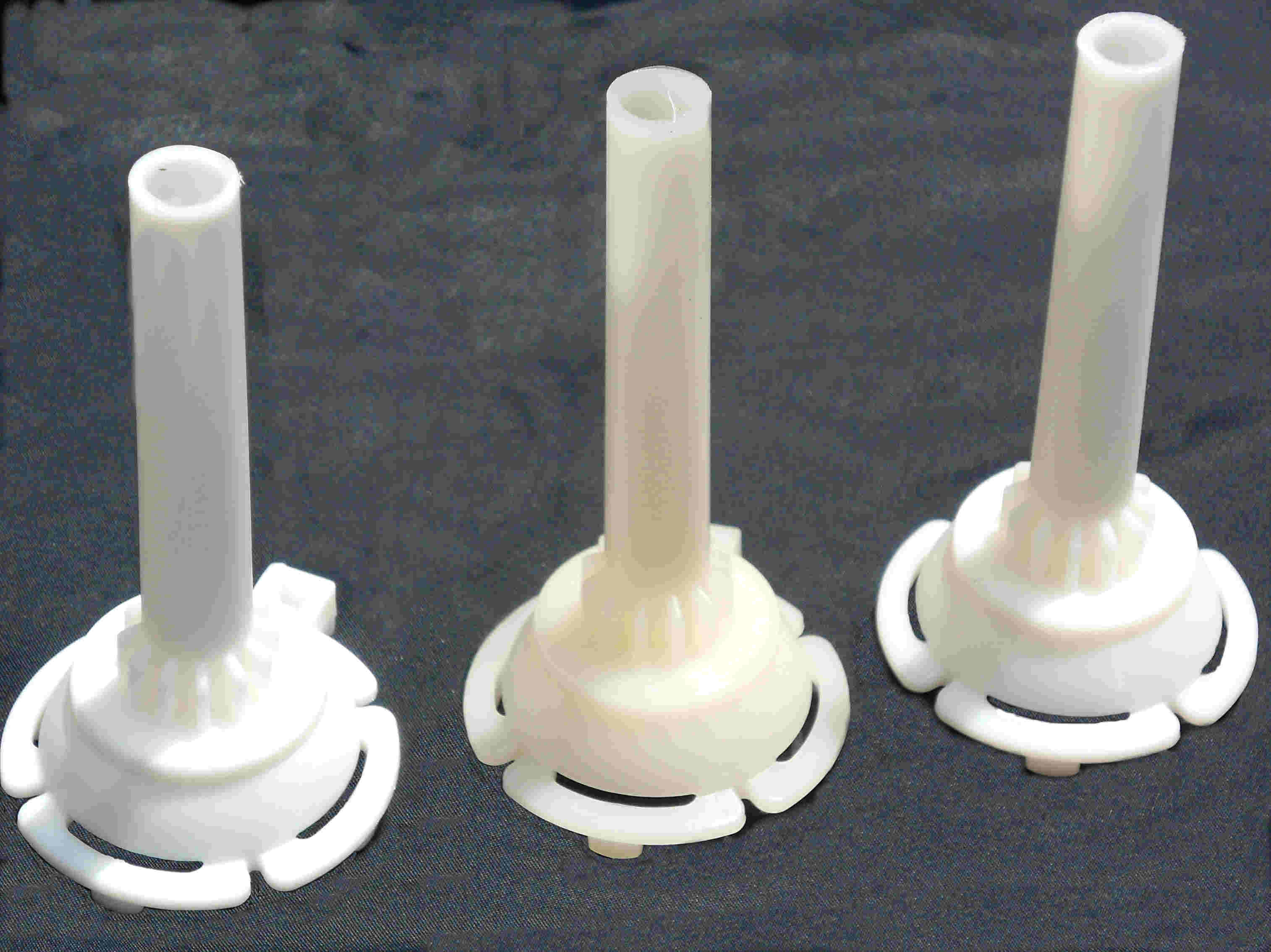

Final 3 Best Super Handles samples received on July 9, 2018.

Left and Middle CX40 samples handles were rejected, Right handle CX40 samples

were put under continuous cycle testing and user testing.

About 4+ days latter we got some initial feed back comments from our CX40 Joystick Super Handle testers. In side by side comparisons (both stock CX40 Joysticks, one fitted with the Best CX40 Super handle and the second one with the last Generation of the Atari CX40 lobed CX40 handle) 8 of 10 of the CX40 Joystick testers said the stock CX40 Joystick with the stock handle had a slightly softer feel to the Joystick handle travel distance (because of the very very thin ring of the bottom of the stock CX40 handle ring compared to the thicker / reinforced / Beefed up Best CX40 Super handle ring) of the handle in all directions. 9 out 10 of the CX40 testers said the tighter / stiffer / precise feel of the Best CX40 Super handle samples were a big improvement (more precise game play) over the softer feeling stock last generation of Atari CX40 lobed handle. On the Best CX40 Super Handle Joystick they said you can still feel and hear the CX40 Gold lifetime PCB board dome contact click sound / tactical feed back feature. Most of the CX40 Super handle testers said they could feel the beefed / thicker bottom CX40 ring flex up and down to a degree after the dome contact had bottomed out.

Day 6 of the continuous cycle / game testing of the CX40 Super handle Joysticks, Engineering dissembled all test CX40 Joysticks and each well used Best CX40 Super handles was inspected under magnification for cracks, white stress marks and any distortions on the bottom joystick rings. To our surprise not a single New CX40 Super Handle sample showed any of the standard failure problems that all of the CX40 Super Handle past samples have shown for the last 29+ months of the CX40 Super Handle project. With this promising test results so far, the CX40 Super handle well used samples were again installed back into the CX40 Joysticks and the continuous cycle / game testing continued.

About a week later of continuous testing, the same disassembly / Inspection process was again done and again not a single problem was detected. At this point Best Engineering felt this new plastic molding compound was the best choice for the Best CX40 Super handle. Although they said, they would still continue the long life cycle testing for the rest of the month. Engineering sent a new 1st article receiving report back to our New Injection Molder telling them this was the approved plastic molding compound for the Best CX40 Super Handle.

After 10+ days of

After a total of 17+ days of continuous cycle testing and user testing of the final Best CX40 Super handle samples, another Quality Assurance inspection was done on the test CX40 handles, same test results, no stress marks were found on the bottom ring of the Joystick handles. Best estimates the continuous cycle testing and user testing done so far, would be equal to about 2 to 3+ years of normal to hard Atari CX40 Play / Use. At this point in the testing, Best was comfortable giving the final approval of this New plastic molding compound to our new Injection molder. Although Best continued with the continuous cycle testing and user testing to see when the new CX40 Super Handles would start to show any white stress marks on the bottom Joystick ring.

The New 2018 Best CX40 Super Handle CO12116-SH $12.95 (Min. Qty 2)

Now for the 1st time in the last 2+ years the very popular Best CX40 Atari Joystick Gold rebuild kits are back in stock with the just released 4th Gen. Best CX40 Gold PCB boards and Brand New 2018 Upgraded / Improved Best CX40 Super handles. CB101211UG-4th GEN $20.95

New CX40 Joystick upgraded with Best 4th Gen. Gold Lifetime PCB board, Bests New 2018 CX40 Upgraded / Enhanced CX40 Super Handle. CX40-GSH $34.95

New

Add Best Electronics All Atari Web site to your Internet Explorer Favorites folder.

Copyright © 2002

Best Electronics in the Atari business since February 1, 1984.

This page Last modified: February 02, 2025

Back to Best Home page

Phone: 408-278-1070 (1:30 - 5 PM, PST, M - F)

Caller ID # required on all phone calls to Best

Current

Pacific

Standard

Time

is:

E-Mail: